Strut Systems Installation was recently contacted by a major university to assist in a construction project involving implementation of a new raised access flooring system. This project had areas that required increased loading capacity which exceeded the original design limitations.

SSI was asked to design and construct a Unistrut structure beneath the raised flooring panels, with the intention of increasing the overall loading capacities of the floor system. Through careful planning and design, we were able to accomplish the retrofit without impacting the functionality of the access floors.

What Is A Raised Access Floor?

Raised access floors are a type of flooring system constructed above a building’s original concrete slab, creating an open space between the two surfaces. This elevated floor is typically made up of modular panels supported by a grid of pedestals and stringers, allowing for easy removal and access.

One of the primary benefits for companies using raised access floors is the improved organization and management of cables, electrical wiring, and HVAC systems, which can be routed beneath the floor and easily accessed for maintenance or upgrades. This not only enhances the safety and aesthetics of the workspace by reducing clutter but also supports flexibility in office layouts and technological changes. Additionally, raised floors can contribute to better air circulation and energy efficiency, especially in data centers and other environments with high cooling demands.

Limitations of Customer’s Existing Access Flooring

Load capacity is a critical consideration when designing and installing a raised access floor system, as it directly impacts the safety and functionality of the space. These floors must be engineered to support various types of loads, including static loads (such as heavy equipment), dynamic loads (like rolling carts), and concentrated loads (such as server racks).

If the load capacity is not properly calculated or the system is not adequately reinforced, the panels or supporting structure may deform, crack, or even collapse, posing safety risks and potential damage to equipment. It’s essential for companies to accurately assess the expected load requirements and choose flooring components such as panels, pedestals, and understructure that meet or exceed those needs.

Our customer intended on storing heavy equipment on the raised access floors, with weights far exceeding the loading capacity of the original flooring system’s design. Our custom Unistrut system added significant strength to the existing raised access flooring system, giving the client peace of mind knowing their equipment would be secure and well within the parameters of the access floor’s newly increased load capacity.

Building Raised Access Flooring from Unistrut Metal Framing

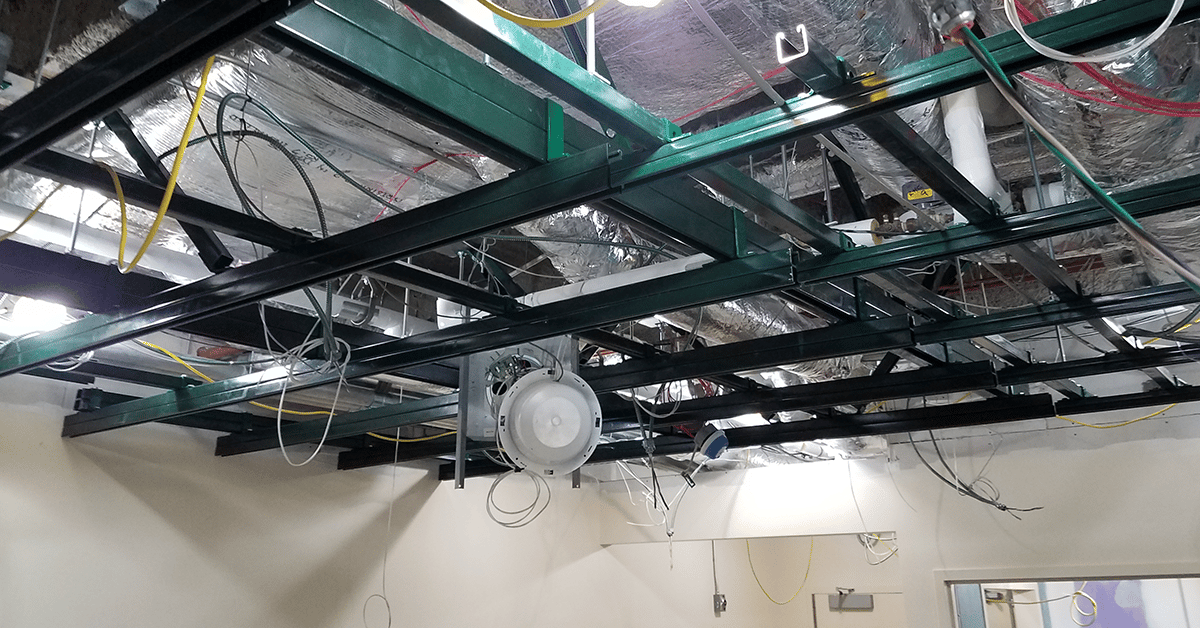

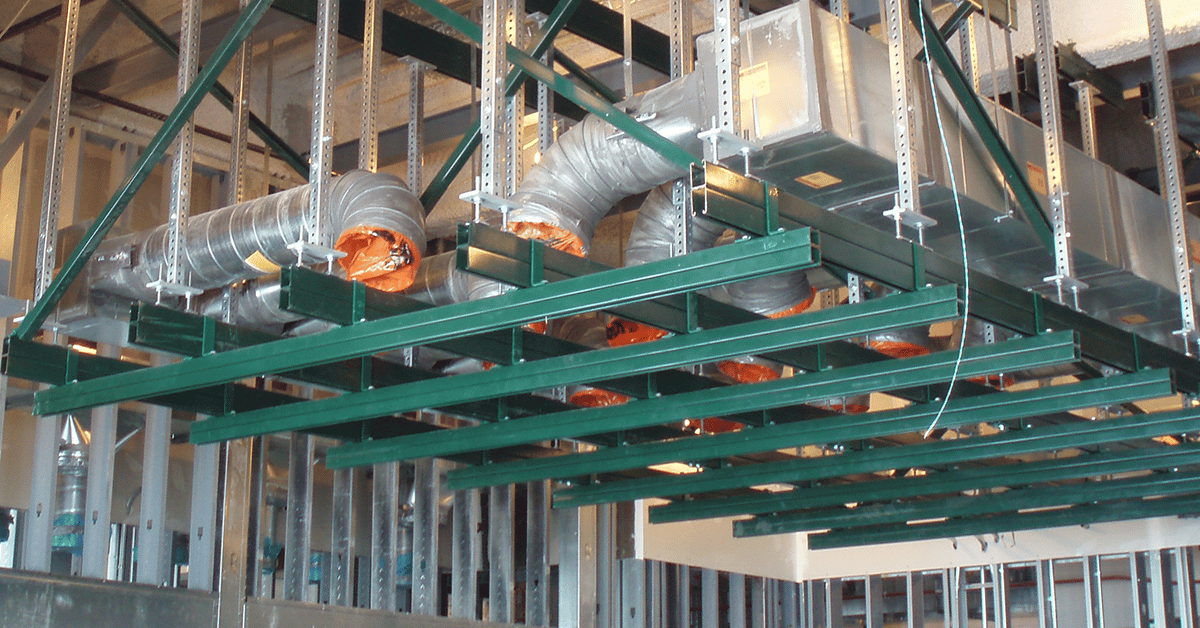

SSI developed a custom Unistrut support system beneath the raised access flooring panels by first conducting a thorough structural analysis of the anticipated load requirements, including point loads and uniformly distributed loads from heavy equipment. The design process began with mapping out the layout of the raised floor and identifying high-load zones. Based on these zones, we designed a grid of Unistrut channels to be installed beneath specific floor panels, using structural-grade steel channels anchored securely to the building’s subfloor.

The spacing, orientation, and anchoring points of the Unistrut were calculated to distribute the load evenly and prevent deflection or point stress. During installation, adjustable pedestals were mounted directly onto the Unistrut channels to transfer loads directly into the reinforced framework. The system was tested and verified using load simulations and, where applicable, physical testing to ensure compliance. This robust support solution not only increased the floor’s load-bearing capacity but maintained full access to underfloor utilities and preserved the flexibility of the modular flooring system.

Why Your Next Raised Access Flooring System Deserves the Experts at SSI

Upon successful completion, the university was very pleased with our custom Unistrut system, which dramatically increased the load capacity of their existing raised access flooring without compromising its core functionality or versatility. Our solution allowed them to safely install and operate heavy equipment with full confidence in the structural integrity of their floor system, all while maintaining easy access to underfloor cabling and infrastructure. The seamless integration of the Unistrut support ensured that the modular nature and adaptability of the raised flooring remained intact, allowing for future reconfigurations if needed.

Strut Systems Installation’s ability to engineer tailored, high-performance solutions while preserving the flexibility our clients rely on, sets us apart from the competition. With a proven track record of precision, reliability, and customer satisfaction, SSI is the ideal partner for your next project requiring smart, load-bearing innovations in raised access floor design. Contact us today to discuss your project needs!